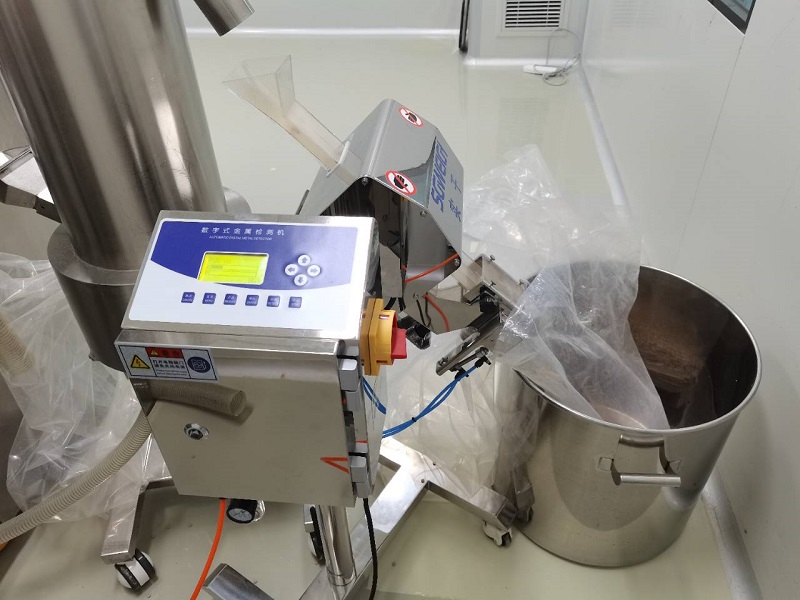

The cleaning of Pharmaceutical Metal Detector Machine is a key step in ensuring their accurate operation and extending their service life.The following is a detailed explanation of the cleaning method for pharmaceutical metal detection machines:

Choose appropriate cleaning agents and tools:

Use professional cleaning agents or diluted alcohol for cleaning, and avoid using cleaning agents that are corrosive to the equipment.

Use soft fabric or alcohol swab for wiping, avoid using hard brushes or rough fabrics to avoid scratching the surface of the equipment.

Turn off the power and disconnect:

Before cleaning, be sure to turn off the power of the pharmaceutical metal detection machine and disconnect it from the power cord to ensure safety.

Dismantling detachable components:

Remove the components that need to be cleaned, such as conveyor belts, detection boards, etc., for a more thorough cleaning.

Remove dirt and residue:

Gently wipe the surface and interior of the equipment with a cleaning agent or alcohol swab to remove accumulated dirt, dust, and residue.

For dirt that is difficult to remove, professional cleaning agents or diluents can be used for soaking and cleaning.

Drying treatment:

After cleaning, use a clean cloth or hair dryer to dry the surface and interior of the equipment to avoid moisture residue that may cause damage to the equipment.

Reassemble and inspect:

Reassemble the cleaned components onto the equipment and ensure that all connections and fixings are secure and reliable.

Start the device and check its operating status to ensure that it can function properly after cleaning.

Regular maintenance and upkeep:

In addition to daily cleaning, regular maintenance and upkeep of pharmaceutical metal detection machines should also be carried out, such as replacing worn parts and checking the sensitivity of sensors.

Follow the operation and maintenance instructions provided with the equipment for maintenance and upkeep work.