An Automatic Checkweigher is an industrial machine used for checking the weight of products during or after the manufacturing process. It is a critical component in quality control and ensures that products meet specified weight criteria. Checkweighers are commonly used in various industries, including food and beverage, pharmaceuticals, cosmetics, and manufacturing.

Weighing Accuracy:

Checkweighers are designed to provide accurate weight measurements for each product. They use precision load cells and sensors to achieve high levels of accuracy.

Dynamic Weighing:

Automatic checkweighers are capable of weighing products in motion as they pass through the conveyor system. This allows for high-speed and continuous weighing in a production line.

Integration with Production Line:

Checkweighers are often integrated into existing production lines. They can be positioned after filling or packaging processes to ensure that each product meets the specified weight requirements.

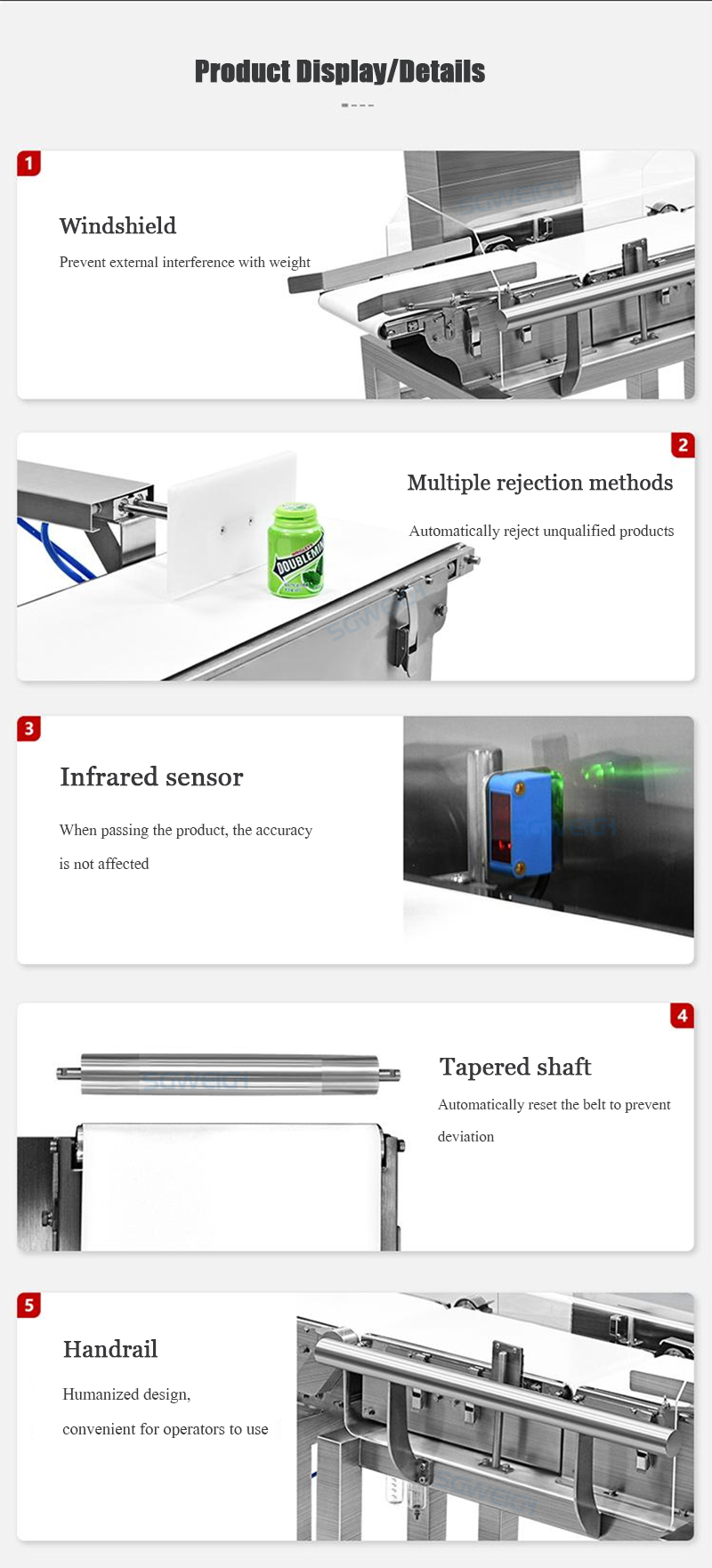

Reject Mechanism:

If a product is outside the acceptable weight range, the checkweigher triggers a reject mechanism to remove the non-compliant item from the production line. This can include mechanisms such as air jets, pushers, or conveyor belts.

User Interface:

Checkweighers typically have user-friendly interfaces for operators to set up, monitor, and adjust parameters. Touchscreen interfaces are common, allowing for easy configuration and data access.

Data Logging and Reporting:

Many checkweighers are equipped with data logging capabilities, allowing for the recording of weight data for each product. This data can be used for quality control, process optimization, and compliance reporting.

Speed and Throughput:

Checkweighers are designed to operate at high speeds to match the pace of production lines. The throughput capacity is an important consideration based on the production requirements.

Customizable Settings:

Checkweighers often come with customizable settings to accommodate different product types, sizes, and weight tolerances. This flexibility is essential for handling diverse product lines.

Compliance with Standards:

Depending on the industry, checkweighers may need to comply with specific standards and regulations. Ensure that the chosen checkweigher meets the necessary industry requirements.

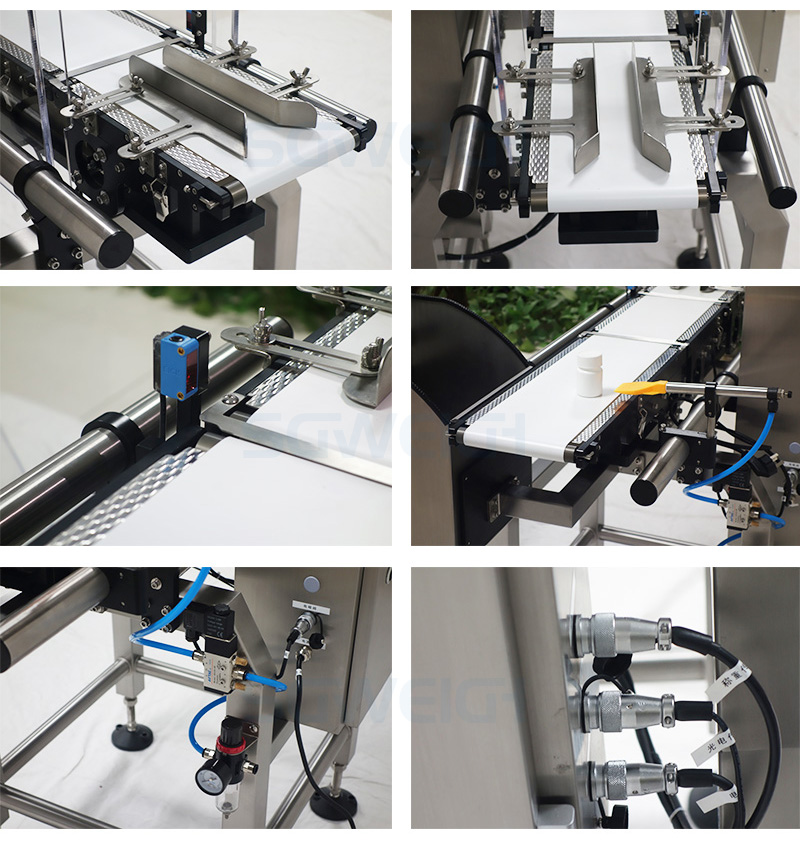

Easy Maintenance:

Maintenance is a crucial aspect of any industrial equipment. Look for checkweighers that are designed for easy maintenance, with features such as tool-free belt removal and quick-change components.

Size and Footprint:

Consider the size and footprint of the checkweigher to ensure it can be easily integrated into your production line layout.

When selecting an automatic checkweigher, it's important to consider the specific needs of your production process, the types of products you are handling, and the required accuracy levels. Consulting with manufacturers or suppliers can help you choose the right checkweigher for your application.