The Automatic Fruit Multi-Level Weight Grader Machine adopts high-tech, high-speed control of single-chip microcomputer, which is used to detect whether the weight of the product is consistent with the target set in the interval, and the product is automatically selected by the sorting device.Multi Weight Sorting Machine With Conveyor Belt has a built-in world advanced digital weighing unit,which can realize high-speed, accurate and stable measurement.It is widely used in the integrated industry of automatic production and packaging.Welcome to consult for quotation information !

Type SG-D220

Weighing Range 10-1200g

Limited of product L: 200 W:150 H: 3-200mm

Accuracy ±0.2 Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 100 pcs/min

Belt Width 220mm

Machine Weight 60kg+44kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

For reference only, please consult for details!

Contact us to recommend a product that is suitable for you!

1. Accuracy

Imported high-speed weighing modules and weight sensors can be used to ensure the accuracy of calibration.

2. Structure

Simple Comply with GMP and HACCP standards, all made of stainless steel, simple structure, easy maintenance and maintenance.

3. Convenient operation

It adopts Schneider touch screen, easy to operate, intuitive display, and supports multiple languages (default Chinese and English).

4. Convenient external connection

It can be connected with other equipment in the production line, such as printers, labeling machines and inkjet printers (customized).

5. Wide application

It is suitable for checking the weight of packaging bags and filled packages, and there are a variety of rejecting methods to choose from (pull, blow, push, etc.).

6. Automatic feedback function

The signal is provided to the front end, and the packaging accuracy is fed back in time to adjust the feeding status of the connected equipment.

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

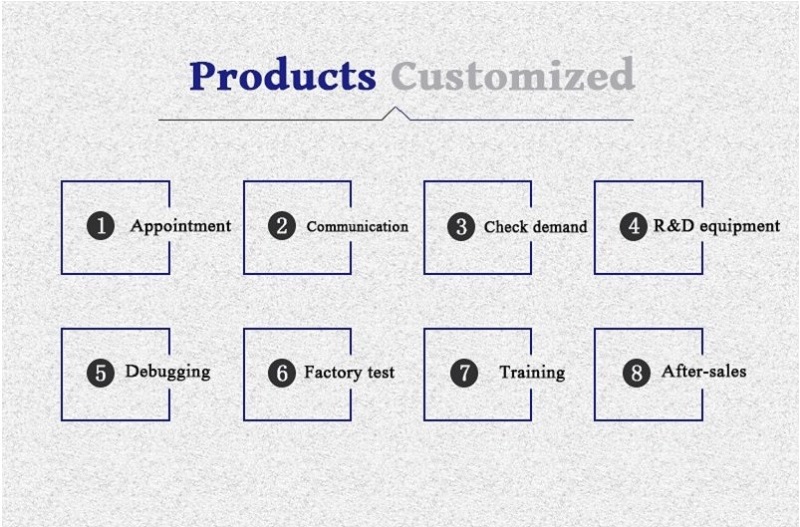

★Pre-sales

project design,performance introduction,technical agreement,contract signing,production testing and we can customized production according to your requirements.

★In-sales

we will provide you with the latest process in the product assembly,packing and transportation.

★Installation

◎We provide videos and instruction manual to show the process of installation.

◎We provide training for installation for free in our factory.

◎We can send technician to buyer's factory to install the machine and provide training service.

★After-sales

◎ For our machines, we will provide some spare parts and easy broken parts free of charge when delivering.

◎We will have one year free warranty period. During warranty period, if there is any malfunction for the machine, we will try our best to solve the problem within 24 hours. If there are some spare parts needed to be replaced, we will provide the spare parts for free. Beyond warranty, we will charge the cost price for spare parts.