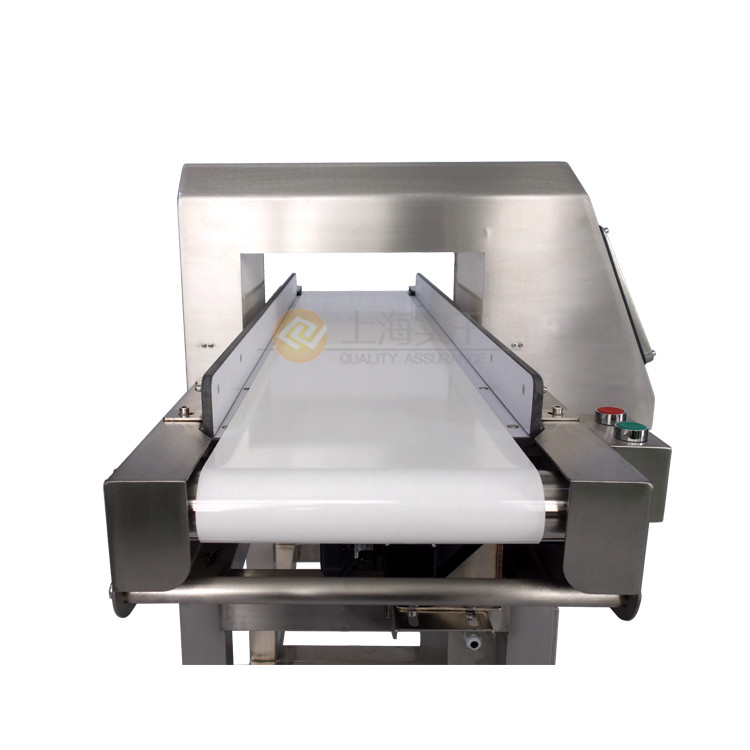

Frozen Food Online Metal Detector uses high-speed digital signal processing devices and intelligent algorithms to detect metals in frozen foods, meat, rice, pickled products and other foods. The use of high-speed digital signal processing devices and intelligent algorithms improves detection accuracy and stability.High Performance Sensitive Metal Detection Machine has high detection sensitivity for metal foreign matter mixed in products; it can easily detect common metal impurities mixed in products.Welcome to consult for quotation information !

SG-M400

Detection sensitivity: in empty state

H-100mm: Fe≥Φ0.8mm, Non-Fe≥Φ1.5mm, SUS≥Φ1.5mm

H-120mm: Fe≥Φ0.8mm, Non-Fe≥Φ1.5mm, SUS≥Φ2.0mm

H-150mm: Fe≥Φ1.0mm, Non-Fe≥Φ1.5mm, SUS≥Φ2.0mm

H-200mm: Fe≥Φ1.2mm, Non-Fe≥Φ2.0mm, SUS≥Φ2.5mm

Effective detection hole width: 150-1000mm customized according to requirements

Effective detection hole height: 80-500mm customized according to requirements

Maximum speed of conveyor belt: 25m/min

Conveyor belt material: food grade PU belt

Protection class: IP65

Display and operation mode: LED falt key input

Machine weight: about 120kg

Power requirements: AC220V 50HZ

Power: 200W

Alarm mode: metal detection, alarm belt stop or automatic removal

Dimensions: about L1500×W850×H950mm

· Detect all types of metal contaminants, including ferrous, non-ferrous, and extremely difficult-to-detect non-magnetic stainless steels.

· Phase adjustment technology effectively suppresses product signals; high-speed digital signal processing technology and intelligent algorithms.

· Dual-frequency detection takes into account the detection sensitivity of dry/wet products.

· Stable and reliable, advanced automatic compensation technology ensures long-term stable performance.

· Customizable, in addition to standard specifications, it can be customized according to different user requirements.

· Efficient operation: automatic settings, quick product switching, no product handling, historical data, multi-language operating system, etc.

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

1.Product quality commitment

(1).There are quality records and testing data for the manufacture and testing of products.

(2).For the inspection of product performance,we sincerely invite users to inspect the whole process and performance of the product in person.After the product is confirmed to be qualified,it will be packaged and shipped.

2.the product price commitment

Under the same competitive conditions, our company will sincerely provide you with a preferential price on the basis of not reducing the technical performance of the product or changing the product components.

3. Delivery time commitment

Product delivery time: as far as possible according to user requirements,if there are special requirements, it needs to be completed in advance,and strive to meet user needs.