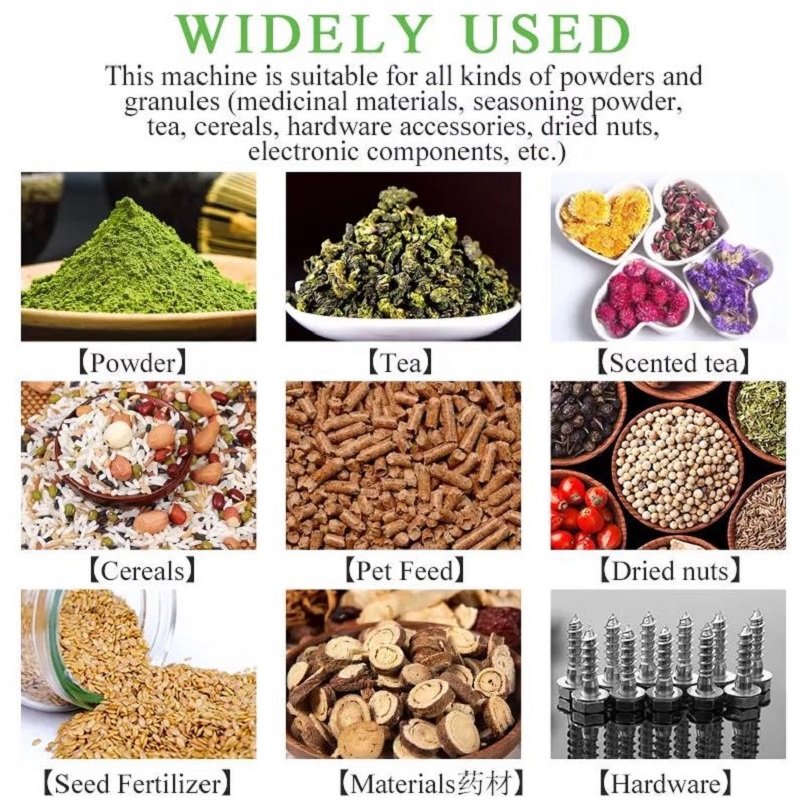

High Accuracy Food Processing Check Weigher have gradually become an indispensable link in modern industrial production,especially in the production process of the food industry.Automatic checkweighers are specially designed for manufacturers who produce online weighing and product weight control.Check Weigher With High Hygiene Standards can adapt to almost every kind of packaging, bags, cartons, boxes and bottles.Welcome to consult for quotation information!

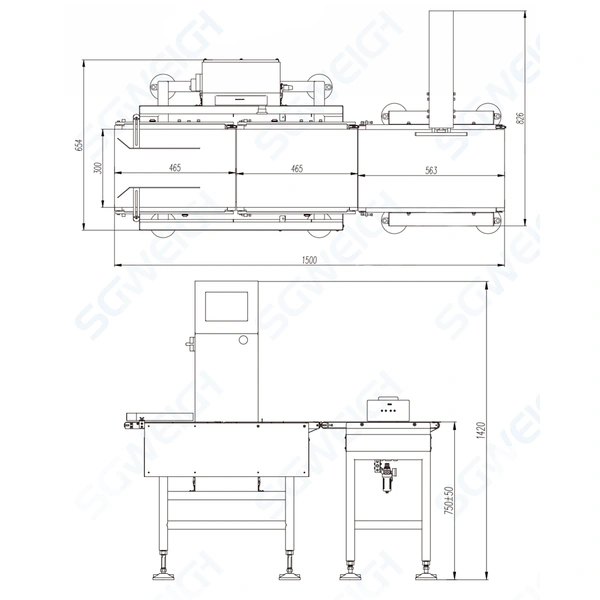

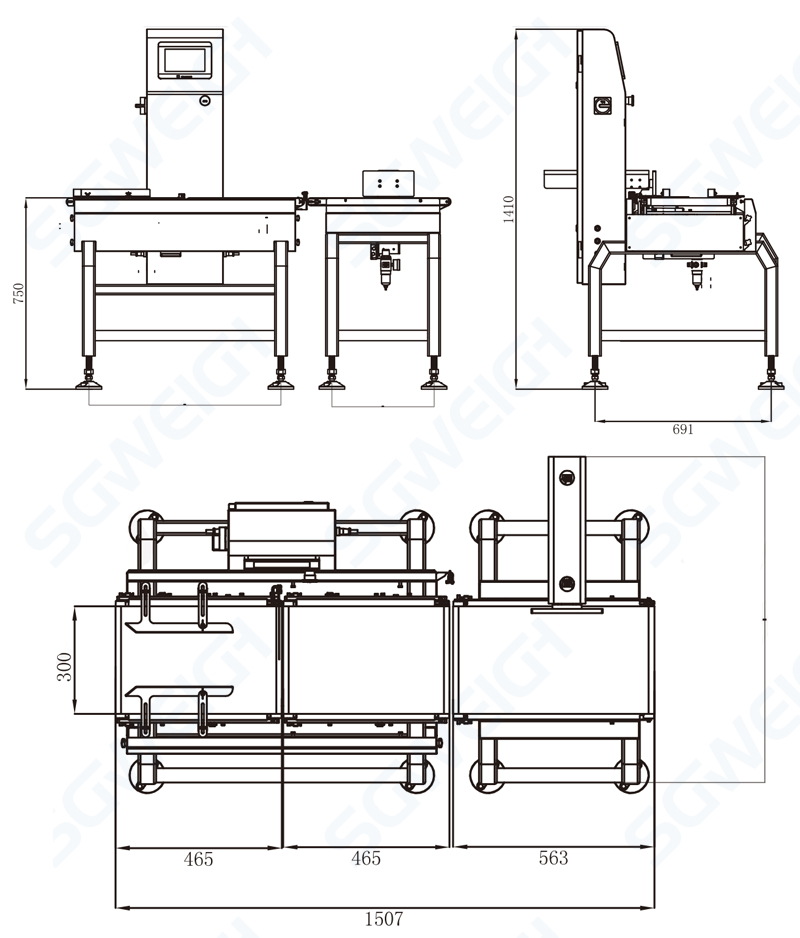

Type SG-300

Weighing Range 5-3000g/5000g

Limited of product L: 350 W:300 H: 3mm

Accuracy ±0.3-0.5g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 80 pcs/min

Belt Width 300mm

Machine Weight 100kg

Power Supply AC 110/220V ±10% 50HZ

Power 200W

Main Material SU304 stainless steel

Automatic selection - automatic selection method, convenient and fast;

Adjustable speed - high-precision detection, adjustable conveying speed;

Parameter settings - upper and lower limit weight parameters can be set arbitrarily;

Frequency conversion speed regulation - the conveying system adopts frequency conversion speed regulation mode to facilitate speed regulation;

Data storage - powerful data statistics function, recording daily detection data;

Data recall - with set data group memory and recall functions, easy to operate;

Data recording - OK number, underweight number, overweight number are accumulated respectively;

Fault diagnosis - self-fault diagnosis and prompt function to facilitate maintenance;

Multiple groups of storage - can store 100 groups of setting parameters;

Processing method - alarm/stop for non-conforming products, optional rejection.

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

★Pre-sales

project design,performance introduction,technical agreement,contract signing,production testing and we can customized production according to your requirements.

★In-sales

we will provide you with the latest process in the product assembly,packing and transportation.

★Installation

◎We provide videos and instruction manual to show the process of installation.

◎We provide training for installation for free in our factory.

◎We can send technician to buyer's factory to install the machine and provide training service.

★After-sales

◎ For our machines, we will provide some spare parts and easy broken parts free of charge when delivering.

◎We will have one year free warranty period. During warranty period, if there is any malfunction for the machine, we will try our best to solve the problem within 24 hours. If there are some spare parts needed to be replaced, we will provide the spare parts for free. Beyond warranty, we will charge the cost price for spare parts.