The High Performace Cashew Metal Detector Machine is using checking metal mix in cashew kernel and remove before packing and finished.The conveyor belt is made of high-quality food-grade belts, which are made of special materials and manufacturing processes.Food Grade Conveyor Metal Detector Machine have high sensitivity,strong anti-interference ability,and stable performance.Welcome to consult for quotation information !

Detection sensitivity: in empty state

H-100mm: Fe≥Φ0.8mm, Non-Fe≥Φ1.5mm, SUS≥Φ1.5mm

H-120mm: Fe≥Φ0.8mm, Non-Fe≥Φ1.5mm, SUS≥Φ2.0mm

H-150mm: Fe≥Φ1.0mm, Non-Fe≥Φ1.5mm, SUS≥Φ2.0mm

H-200mm: Fe≥Φ1.2mm, Non-Fe≥Φ2.0mm, SUS≥Φ2.5mm

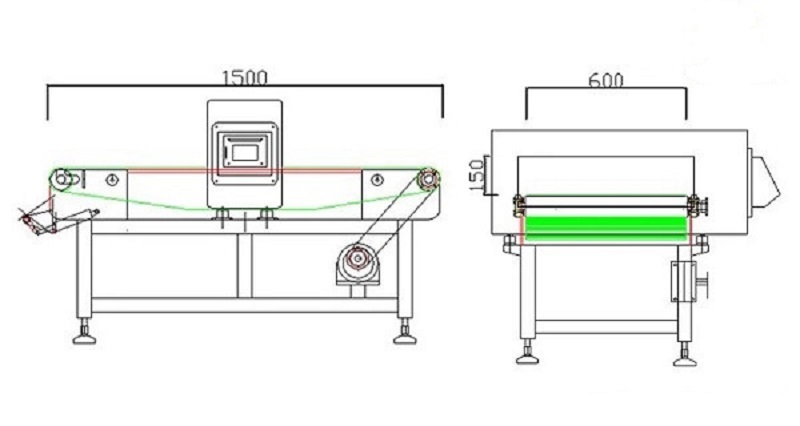

Effective detection hole width: 150-1000mm customized according to requirements

Effective detection hole height: 80-500mm customized according to requirements

Maximum speed of conveyor belt: 25m/min

Conveyor belt material: food grade PU belt

Protection class: IP65

Display and operation mode: LED falt key input

Machine weight: about 120kg

Power requirements: AC220V 50HZ

Power: 200W

For reference only, please consult for details!

Contact us to recommend a product that is suitable for you!

1.Metal detector machine dopts highly human-oriented and intelligent design and has the function of one-bottom self-learning.The machine can set and store product parameters automatically and precisely when the products to be detected passing metal detector according to set procedure, no need to adjust by human.

2.Metal detector machine can store 100 kinds of products parameters,and once the products parameters are set,no need to adjust again,can automatically detect faults when booting and has the function of prompt, which can effectively eliminate invalid detection.

3.The metal detector machine adopts modular design and installation,which benefits for assembly and disassembly, having advantages of convenient maintenance and low cost for maintenance.

4.Customization can be provided according to detecting products’ sizes,weight and characteristics in order to achieve best detection sensitivity.

5.The rejection system and control system can be customized according to production line’s features, which can enhance production efficiency.

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

Online Checkweigher

Food Checkwiegher

Large Range Checkweigher

Multi-Lane Check Weigher

Pharmaceutical Checkweigher

Weight Labeling Machine

Food Metal Detector

Industrial Metal Detector

Metal Detector Combination Checkweigher