1. Checkweigher is divided into Static Checkweigher and Dynamic Checkweigher

Checkweighers must be divided into dynamic checkweighers and static checkweighers.

Static Checkweigher

The product must be manually placed on the scale for weighing. Accurate weighing results can be obtained with static checkweighers, but this process can only be performed by sampling.

Dynamic Checkweigher (Automatic Checkweigher)

For monitoring and sorting standard piece goods by weight during production. This is automatic weighing (100% control) of all produced products, and the products on the conveyor belt are weighed continuously, ie in a dynamic state. In this case, it is not the checkweigher itself that determines when the checkweigher outputs a weight value, but rather the production rate.

2. Application of automatic checkweigher

Checkweighers can be permanently integrated into production lines to check products in production at high production speeds. Our company has different types of checkweighers, according to the industry and products used, choose the solution that suits you.

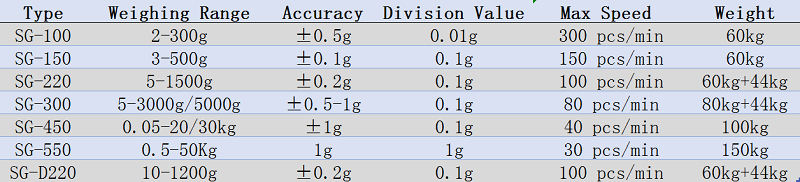

If the volume requirement is high, a large-capacity checkweigher—SG-550 can also be used.

2-300g choose SG-100 checkweigher.

3-500g choose SG-150/SG-150H checkweigher.

5-1500g choose SG-220 checkweigher.

5-3000g/5000g choose SG-300 checkweigher.

50g-20000g/30000g choose SG-450 checkweigher.

10-1200g choose SG-D220 multi-level checkweigher.