The Double Probe Conveyor Metal Detector Machine has the function of automatically removing metal foreign objects detected, and the length and size of the machine can be designed and manufactured according to requirements.Intelligent Adjustable Metal Detector adopts European and AmericaThere are many kinds of products,welcome to consult for information and quotation !n standard design, the whole machine design meets the mechanical requirements of many industries, and is suitable for connecting assembly line inspection operations.

1. Rack size: Length: 1700mm, Width: 900mm, Height: 1100mm

2. Effective detection aperture: 500mm*300mm

3. Conveyor belt height: 750mm±50mm

4. Conveying speed: about 30 m/min

5. Detection index: iron (Fe)≥φ2.0mm, non-ferrous (Non Fe)≥φ3.0mm, stainless steel (Sus)≥φ3.5mm

6. Body material: all 304 stainless steel body

7. Conveyor belt: white food grade conveyor belt

8. Protection level: IP65

9. Ambient temperature: (-10~50) degrees Celsius

10. Power supply and voltage: single-phase 220V/50HZ

11. Alarm: sound and light alarm

For reference only, please consult for details!

Contact us to recommend a product that is suitable for you!

1. Improve the detection sensitivity and stability of the machine, and strictly control the product quality.

2. Photoelectric control magnetic field work

3. Sound and light alarm when detecting foreign objects;

5. Automatic counter records the number of detected objects.

6. The conveyor belt stops automatically.

7. Adopt intelligent dual probes to completely eliminate missed detection.

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

★Pre-sales

project design,performance introduction,technical agreement,contract signing,production testing and we can customized production according to your requirements.

★In-sales

we will provide you with the latest process in the product assembly,packing and transportation.

★Installation

◎We provide videos and instruction manual to show the process of installation.

◎We provide training for installation for free in our factory.

◎We can send technician to buyer's factory to install the machine and provide training service.

★After-sales

◎ For our machines, we will provide some spare parts and easy broken parts free of charge when delivering.

◎We will have one year free warranty period. During warranty period, if there is any malfunction for the machine, we will try our best to solve the problem within 24 hours. If there are some spare parts needed to be replaced, we will provide the spare parts for free. Beyond warranty, we will charge the cost price for spare parts.

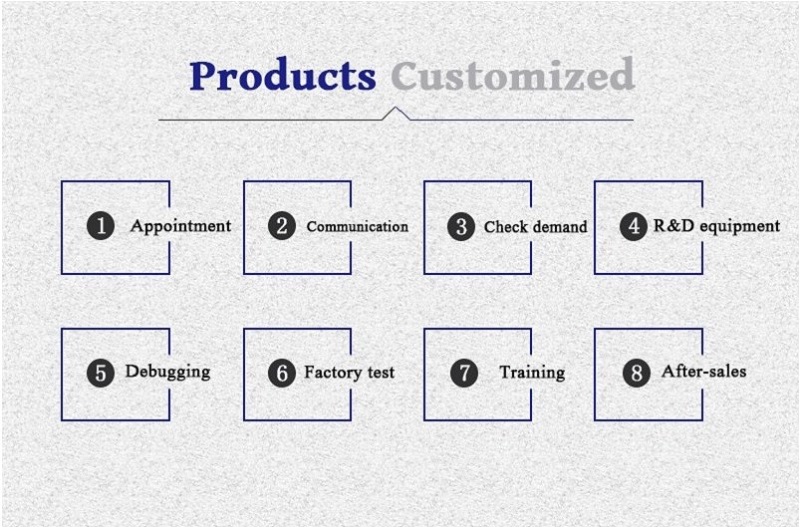

1st step:Customer has showed his special requirements.

2nd step:We try to understand the conception and pattern from customer with simple draft or refer picture.

3rd step:Making the conceptive CAD drawing based on communication and understanding.

4th step:Making the detail and 3D drawing agter fixed the design and other details.

5th step:Offer the quotation after confirm the design,material and surface treament.

6th step:Making the sample for approval.

7th step:Testing installation after demo mock up.

8th step:Big production delivery and service after sales.

Food Metal Detector

Pharmaceutical Metal Detector

Industrial Metal Detector

Vertical Metal Detector

Checkweigher and Metal Detector Combo

Convenient Checkweigher