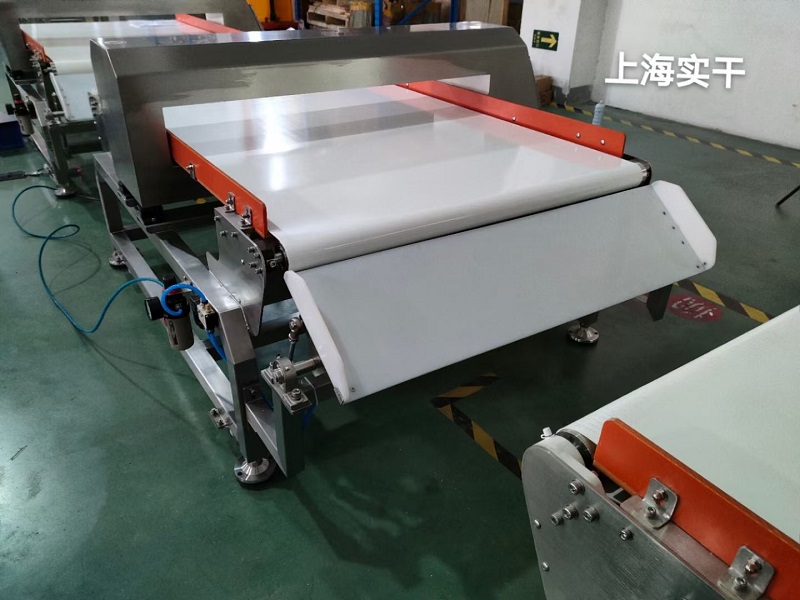

Precision Metal Detector is an intelligent metal detection equipment developed by digital intelligent technology,which realizes the full digitalization and intelligence of metal detection technology,excellent performance,simple operation,and improves the production efficiency of enterprises.Available in a wide range of widths and heights,Ultra-Wide Metal Detectors are ideal for high detection sensitivity and protection for your products.If you are interested in our products,please contact us !

Material: Detector grade 304 stainless steel, frame 201 grade stainless steel, PVC/PU strip.

Belt length (mm): 1600mm.

Conveyor height from belt to ground: 650mm + 100mm ft adjustable, including removable wheels.

Alarm system: buzzer/warning light.

Flow rate: 25 m/min fixed or 10 to 40 m/min variable.

Flow direction: from left to right or vice versa (facing the control panel).

Operating system language: English/Chinese.

Power supply: AC110V/220V, 50/60Hz, power: 90/120/200W.

Deny system:

1. Stop when foreign object is detected (below 50KG) - If metal is detected and an alarm is sounded, the conveyor system will stop allowing the operator to remove contaminated product.

2. Pusher ejector (below 10KG) - Pneumatic pusher transfers the contaminated product out of the production process/belt.

3. Drop down Reject - This rejection mechanism is typically used to remove dry bulk products that are contaminated and/or out of specification. The product passes through the chute, which in the open position allows the continued passage of premium product. Trigger end baffles or lift baffles to divert contaminated or out-of-spec product from a good product flow.

Power supply: AC110V/220V/380V 50/60Hz.

For reference only, please consult for details!

Contact us to recommend a product that is suitable for you!

1. With advanced processing technology and standardized inspection process, the product has high detection sensitivity and stable performance.

2. The structural design of the whole machine is simple, firm and stable. It adopts an all-stainless steel frame, which has strong anti-shock and anti-interference ability, and the protection effect of the electronic control part is good, reaching the protection level of IP66.

3. The automatic deviation correction function is added to the conveying system, and the conveyor belt is made of thermoplastic polyurethane elastomer TPU, which meets the food grade requirements of FDA and EU.

4. With the intelligent LCD display system, the detection parameters can be set conveniently and quickly.

5. With efficient self-learning function, it can effectively suppress the signal of the original product and achieve better results in metal detection.

Applicable to food, health products, daily chemical, pharmaceutical, chemical and other major industries.

Our products can be shipped by sea, air and land.

Q1. Are you a manufacturer or trader?

A: We are a manufacturer and we are located in Shanghai,China. We have our own design team for product design.

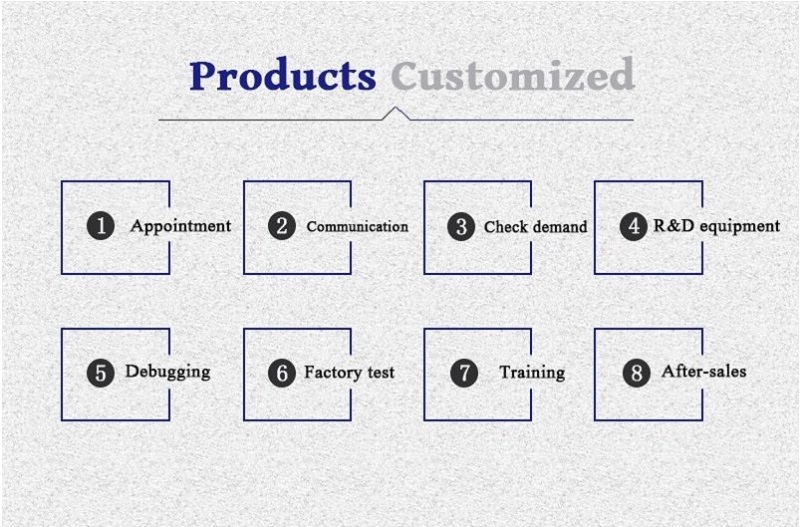

Q2: Can you explain the whole transaction process?

1. Understand the specific needs of customers and determine the machine details.

2. Sign the contract.

3. Pay the deposit.

4. The factory arranges production.

5. Test and inspect the machine before shipment.

6. Check by customers through online or on-site testing.

7. Shipment and transportation, balance payment.

Q3.How much does metal detector cost?

There is no quick, easy answer to this question.Our machine is specific to the customer, so arriving at 'standard pricing' isn't usually practical. Pricing largely depends upon your unique needs, such as the products you want to detect, the size of the product,the speed you want to achieve,or the complexity of the processv. Contact us to get a specific quote.

Q4. What kind of shipping method can you provide?

A: By sea, by air and by international express.We will send the photo and video of machine to customer to check the machine running situation before delivery.

Q5. Do you accept customer logo and customization?

A: We accept all kinds of customization and logo for our customers for all our products.

Q6. How about the packing for product? Is it easy damaged during transportation?

A: No.We takes of wooden case and it is very safe.